Can Store Suction Nozzle Cleaning + Visual Inspection Integrated Machine PBT-80

- Nozzle Cleaning Machine with Inspection System

- Automatic cleaning mode: heating cleaning - spraying, air drying, scanning detection, classification of the whole process completed.

- The whole process visualization window, the cleaning process at a glance.

- Vacuum detection of suction nozzle, the accuracy can be plus or minus 100pA, MES upload function, cleaning and testing process can be traced.

- Can effectively identify and read the two-dimensional code on the suction mouth, and can also read the customer's self-made two-dimensional code.

- The visual nozzle pressure can be adjusted, the nozzle can be detachable, small nozzle in the cleaning of high pressure spray conditions of collision and splashing problem.

- Light transmission detection of suction nozzle inner wall, dirt, blockage, damage.

- The up and down movement smoothness of FUJI suction nozzle can be detected, products can be classified as qualified or unqualified, and can be reflow and re-washed.

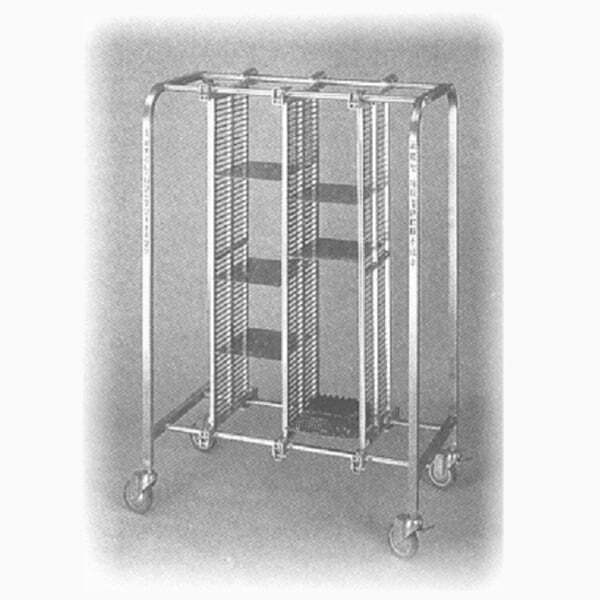

- Different suction nozzles can be stored, up to 3000 suction nozzles can be stored, only need to replace the tray, easily adapt to different suction nozzles.

- The whole process of cleaning, testing and dividing the nozzle is completed, 8 suction nozzle can be completed per minute.

- Pure water cleaning, can be directly discharged, replace the filter element.